Lets Get Your Design On Paper

Starting off with the right information is the key to success. Firstly we will require access to some of your technical documents so that we can assess the interfaces and ensure we specify the right parts that will ensure the maximum performance for your cables.

Do you have a company parts register?

If the answer is yes, we can incorporate all your part numbers into the new drawings. Having this information allows us to put your numbers into a database that will be used as a lookup table and put your part numbers into the bill of materials, having this in place reduces the chances of human error when assigning new part numbers.

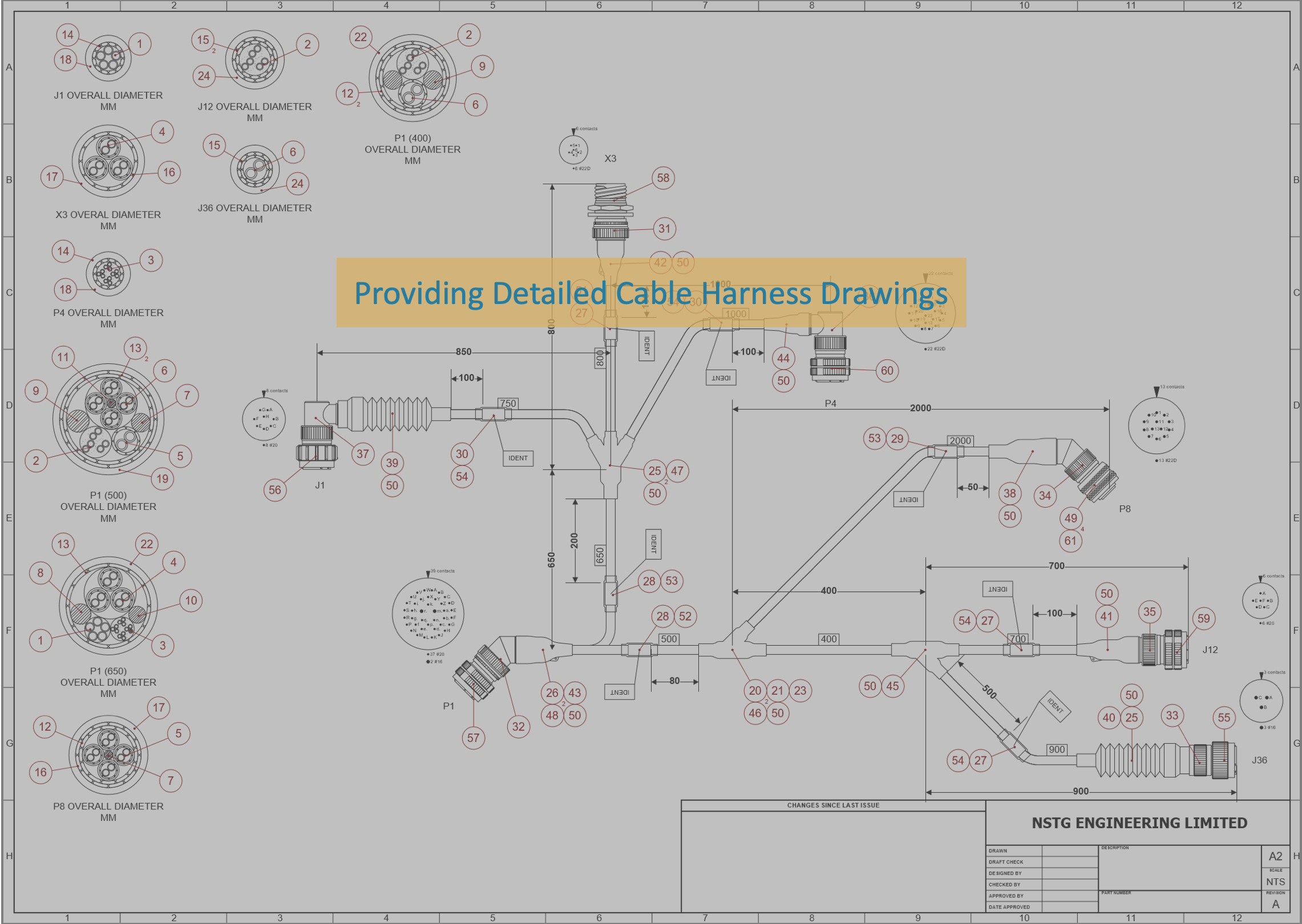

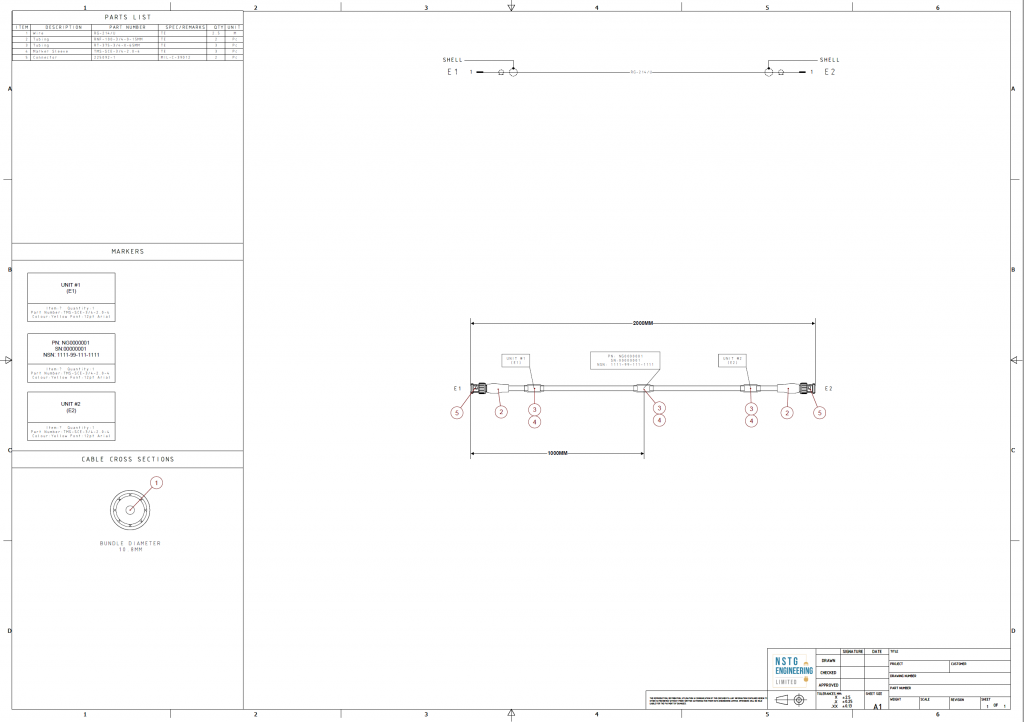

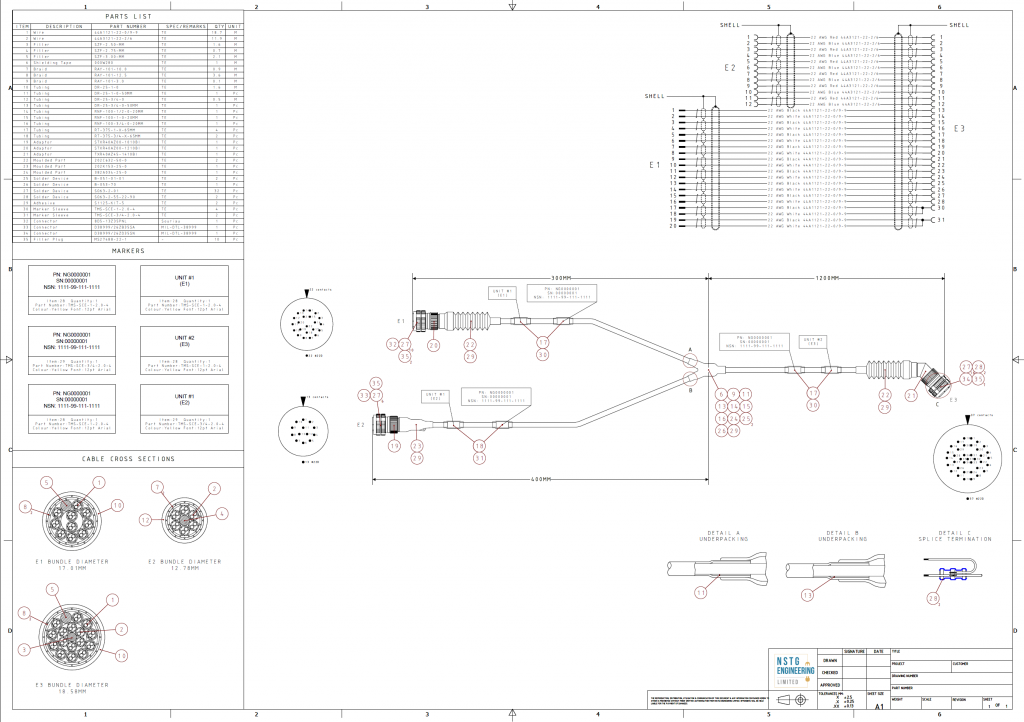

Once we have all the information we will start to produce the cable drawings, all drawings are designed using HarnWare V6.

We always aim to get all the cable harness information onto a single A2 sheet, this sheet will contain the detailed harness drawing, bill of material, cable cross-sections, wiring schematics and all pertinent notes.

Depending on your requirements we can produce manufacture labour estimates, MTBF calculations and also produce an output that shows the RoHS compliance status for all parts in the BoM.

If your system has specific weight requirements, we can provide a separate output that will detail the overall weight of the harness and also provide combined weights for each type of part on the harness.

As part of the HarnWare V6 tool we can also produce 3D files for each harness, these can be manipulated to fit into any of your current CAD models. If you are to manufacture the harness yourself or have a manufacturer that will need to use peg boards to build the harness, an output can be produced to specify the drill hole locations for the pegs. Additional information can also be added to this drawing as required.

As soon as the draft drawings are produced they will be issued to you for review, they will also be sent to the selected manufacturer for review, as it is understood that you may not have the SMEs in your business to thoroughly review every part in the harness.

Once the drawings are formally issued and released to the manufacturer, each drawing will be controlled by the NSTG Engineering Quality Management Database, this ensures that any changes are tracked in a controlled manner.

Drawing Examples

Now that the drawings are complete and signed off, it is time to get them manufactured. See how we can get your cables through the manufacturing process as efficiently as possible.