Combining Expertise To Bring A New Technology That Will Revolutionise Wiring Harnesses

At NSTG Engineering we’re always looking to the future and adopting new techniques and process, so we can offer the best possible solutions to our customers.

By working alongside Q5D Technologies, we’re in a position to offer design and manufacturing services to allow our customers to be able to 3D print wiring harnesses.

This a new manufacturing process that can offer a number of benefits to projects in any industry sector. By adopting this technology at this early stage can give your business or project a competitive edge.

As well as offering design and manufacturing services NSTG Engineering will also be working with Q5D Technologies to lease printers to companies and manufacturers to allow them to produce 3D printed harnesses in house.

About Q5D

Q5D Technologies is made up of two companies CEL-UK and M-Solv.

CEL-UK has developed a 5-axis platform that incorporated a 3D printer and silver based printed electronics, but they were frustrated that the silver paste needed to be cured in an oven. M-Solv had developed a technology that could cure and sinter much less expensive copper inks using a laser, so no separate ovens.

The skills from the two companies combined allow Q5D to offer a wide range of capabilities that can give customers the option to pick a solution that best suits their requirements.

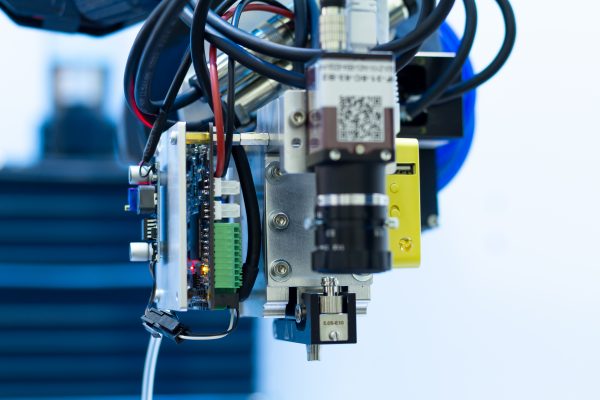

Together they have designed and implemented a modular 5 axis 3D printer that is capable of printing or embedding wiring onto any surface.

Q5D has also developed the software that controls the printer, this has allowed them to develop the printing technology from the ground up and include self-calibration features, and to ensure the software architecture can be scaled for larger printers in the future.

Key Benefits Of 3D Printing Wiring Harnesses

3D printing of wire harnesses is a disruptive technology that can offer wide-ranging benefits to your business and projects. Check out some of the key benefits below.

Reduced Manufacturing Costs

The manufacture of wiring harnesses is labour intensive, the layout is usually done by hand on a pin board.

The use of robotic tools swaps labour cost for the amortised costs of capital and can reduce manufacturing costs by up to 50%.

Improved Safety

The common wiring failures are caused by embrittlement of the insulation due to humidy and UV or because of the ingress of fluids or perhaps because of the ingress of on terminations that leads to corrosion and overheating. These kinds of failures can causes arcing and can eventually lead to fires.

Failure of the wiring is a serious safety issue in the aerospace industry and has caused numerous fires and some notable disasters. It is also the main cause of failure and recalls in white goods and vehicles. It was a wiring failure in a refrigerator that started the Grenfell fire leading to the deaths of 72 people.

Q5D technology embeds the wiring inside a component, protecting the wiring against mechanical and chemical damage, and the use of CAD design on the wiring as well as the structural component means that it can be designed so that the flex on termination stays within the specified tolerance. Systems can be designed for safety.

Reduced Weight

Because harnesses are manufactured by hand and more importantly installed by hand, the gauge of wire is more normally chosen for its mechanical rather than its electrical properties.

Because Q5D embeds wires and printed electronics within a component it is possible to use a gauge appropriate to the electrical load.

Typical weight savings are between 10% and 40% depending on the complexity.

Increased Function

The convergence of IT and manufacturing, as well as electrification in sectors like aerospace and automotive, is increasing the complexity of wiring harnesses. At the same time, there is are strong pressure to decrease weight and cost.

By combining fine gauge wiring, printed electronics with embedded electronics and sensors in a 3-dimensional structure all designed by CAD and robotically manufactured using CAD/CAM, will make it possible to create much more complex systems, with little additional cost or weight.

Improved Quality

The ability to automate manufacture means that each harness is identical. Once a design has been tested then it can be reliably made and used any number of times. If it is manufactured to aerospace standards, then as long as the correct materials are used then every item manufactured using that design will also conform to existing standards. The marking of the wires and document handling part of the quality systems will need to be automated in-line with the new production method. Because the position of the terminations are defined by the design, testing of the wiring can also be automated. This should further improve quality control.

Reduced Development Time

With an automated production tool, it is possible to go from design to manufactured item in a matter of hours. Multiple prototypes can be made and tested, both for their electrical performance and their mechanical properties. This could alter the culture dramatically, making it possible for a designer to optimise a design through multiple iterations and be confident that the final product works. Not only would this save costly design time it would make it possible to create more sophisticated or even bespoke design that performs better.

Simplified Supply Chains

Trade tension and the global pandemic have exposed the fragility of the long and complex supply chains that are used in modern just-in-time manufacturing. The labour-intensive nature of wiring layups often means they are outsourced to low-wage economies, which leads to inexpensive, but unresponsive and complex supply chains. Since the start of the pandemic, there has been a realisation that it is necessary to increase investment in automation.

Printing Methods Available

FFF Head

Print Technology |

Fused Filament Fabrication (FFF)Single or dual Material |

Materials |

PEEK, ULTEM, ABS, PETG, Nylong, glass and carbon filled materials and many others |

Nozzle Diameters |

0.2 mm to 1.2 mm |

Speed |

60 mm/s |

Thick Paste Extruder

Nozzle Diameters |

0.2 mm to 1.2 mm |

Materials |

Silver Paste, Copper paste, ceramic, UV adhesives, epoxy resins, acrylate, silicone, grease, inks, waxes, bio-technical suspensions, abrasive pastes and others |

Thick Paste Extruder

Orifice Diameter |

50 μm – 600 μm |

Materials |

Silver Paste |

Drop Size |

Micro-droplets as small as 0.6 nL |

Jet Speed |

Dispenses at 1000 Hz in continuous mode and up to 1500 Hz in burst mode |

Wire Embedding

Nozzle Diameters |

0.2 mm to 1.2 mm |

Materials |

Silver Paste, Copper paste, ceramic, UV adhesives, epoxy resins, acrylate, silicone, grease, inks, waxes, bio-technical suspensions, abrasive pastes and others |

Laser Sintering

Materials |

Silver and copper paste |

Track thickness |

1 μm to 30 μm |

Conductivity |

30% to 50% of the metal used in the ink |

Want To Find Out More?

If you would like to find out more about the services that NSTG Engineering can offer or find out how this new technology can assist your next project, please fill in the form provided and we look forward to going through your requirements and working with you soon.

If you’re interested in leasing the printers so that you can use this technology in house, there will be a restricted number that will be available initially, but please ensure you tick the “Printer Leasing” option on the contact form and we will add you to the waitlist.