I need these cables and I need them now!!

All too often cables are forgotten about.

Systems engineering have provided a design that satisfies all the customer needs, the software team have produced a truly awesome package with a cracking GUI and the hardware team have brought the project to life.

Now it needs to be tested and accepted by the customer and it’s handed over to the system integration team. They thoroughly test the software and prove that it meets the requirements… Great! Now time to get their hands on the hardware and see it in action…

“Hold on has anyone designed the cables and got them on order? So we can test the full system”.

“No not yet but surely they can’t take that long to make?”

Now this is the point it all goes wrong.

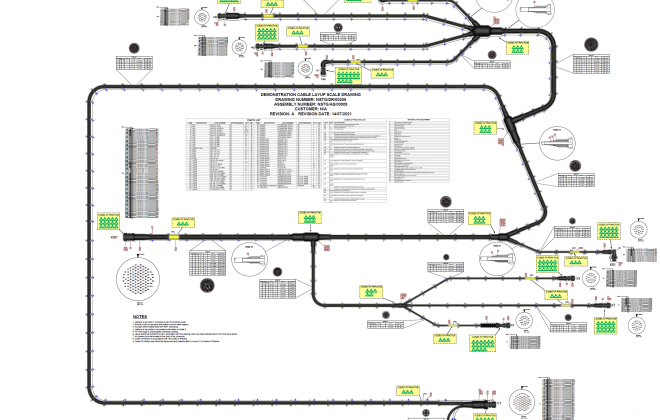

To design a complex cable harness it can take a while, usually between 3 to 6 hours, but it all depends on the amount of connectors, wire types, connections between connectors, selecting the right parts to join multi connector harnesses and of course the tools you use and the recourse you have driving the tool. So if you have 150 unique harnesses to design you soon rack up the man hours.

But unfortunately it doesn’t end there. Now that you have drafts in place all the drawings then need to be checked, reviewed and then approved by multiple members of the project team. Some of these team members may not be readily available to conduct the review or sign off the final drawings for manufacture. Which causes unnecessary stress and elongates the process.

You have to ensure the review is thorough and that every part is checked, there is nothing worse than waiting weeks (or in some cases months) for a cable to arrive, you take one look at it and it has the wrong connector on the end…. It’s a nightmare!

“We have the issued drawings lets get them built, we need them delivered next week”.

Hold your horses there!! Most large or even small business have a strict supply chain process. They have to send the drawings to a number of suppliers to get a (in most cases) fixed cost for the cables and then select the best supplier based on cost and lead time. This process in itself can take up to two weeks as the manufacturer will want to ensure they have correctly priced the project.

“Right now we have the quotes lets get the cables built we need to start testing ASAP, we cannot afford any further delays”.

“Sorry to disappoint, but some of the hardware products have some non standard connectors on them and some of the wire is not stocked”.

This is the biggest “OH CRAP!!!” moment, you see the manufactures lead time on some of the components and they are in the THIRTY week region. This is enough to stop a project dead for months and you already have a customer applying the pressure on you to deliver.

“But why does it take so long?”

95% of the time it’s down to the parts that are selected in the cable harnesses. Some connectors, adapters, backshells, wires and tubing are not stocked, this is due to the demand for those parts is very low, so the manufactures of the parts are not going to waste time and money on building these parts so they can sit on a shelf. So when an order comes in for these rare parts they have to procure the materials and book a slot on the production line. This all takes a long time to complete, which is why the lead time is so long.

When you run into these lead time issues do not be surprised when the part manufacturer asks you to pay for more than what you need. The lowest minimum order quantity (MOQ) for a one off batch of connector I have seen is 25 and the project only needed 2. So you end up paying for a lot of stock. One of the worst items for MOQs are wire and cable, for a one off batch you are looking at buying 2000m.

Now that the cables have been manufactured and arrived you have a truly unhappy customer on your hands, they have waited more than 6 months for the cables and only now can he testing be completed…. Are they likely to come running back to you in the future.. Probably not.

But it doesn’t have to be this way.

Having the right skills at the right time can help to mitigate a huge chunk of the risk. If your company does not have those skills in house, then that’s where NSTG Engineering can help.

From the get go I will firstly review the connectors on your hardware products, if there are any on a long lead time then these will be flagged so that you can get them on order early.

If you don’t have the resources to work out how all your products will connector together, then don’t fear I will help you to define those interfaces. I have had a lot of experience of working on large systems and being given the interface documents for the products and been told to work it out. As systems have become more data hungry the need for reliable Ethernet systems is key, I have worked on a number of systems where the amount of data on the networks has increased 10x from the last time a similar system was built. I understand that in some cases you will need a level of redundancy in your data or power infrastructure, if this is required I can work out the solution and if any single points of failure are remaining these will be highlighted.

I will start the cable design process off as early as possible, this will ensure there is plenty of time to thoroughly review the cables, and it also gives you an insight into the parts that are to be used. Engaging with the cable manufacturer early also helps as they can highlight any potential design issues, they can also look at an early bill of material to assess for long lead items, if the long lead parts can be changed, then great the drawings can be updated, if not then you best get those parts on order early.

There are a lot of external factors that could sink your project, but by getting the right people working out these problems early gives you time to sort any issues that arise.

If you delivered just a few weeks late due to a parts manufacturer failing to deliver on time, would your customer be annoyed.. Probably. But when you show them the steps you had taken to mitigate the risk, would they be willing to come back for a new system… I bet they would.

Related Posts

Leave a Reply Cancel reply

Categories

- Annoucements (4)

- Cable Design (4)

- GVA Cables (1)

- Products (4)

- SNAP (3)