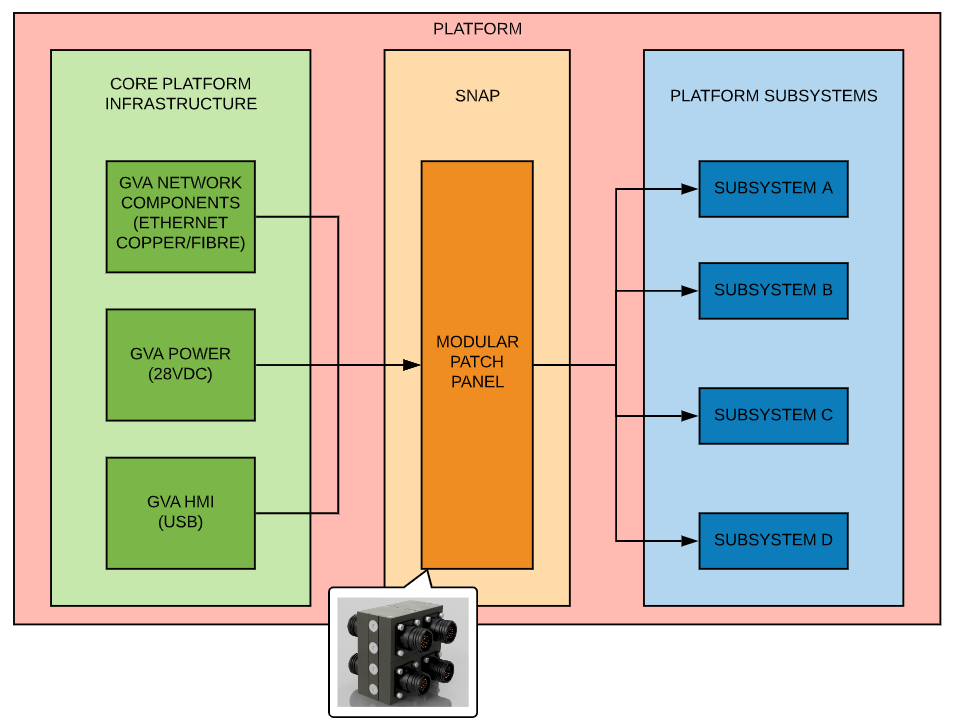

The System Node Access Panel (SNAP), is a modular Generic Vehicle Architecture (GVA) compliant patch panel designed for the land military environment. SNAP provides a flexible solution which bridges the gap between the core vehicle electronic architecture and installed subsystems.

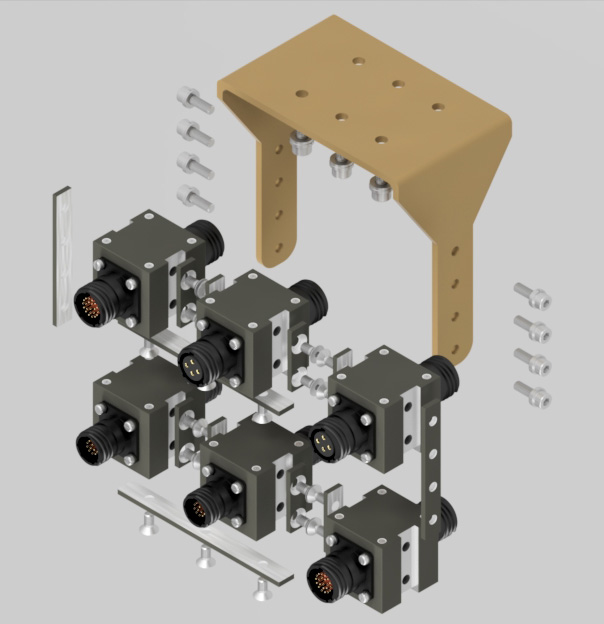

SNAP provides a building block approach to constructing a GVA patch panel, this is achieved by supplying a number of modules that are identical in size and fixing arrangement. This enables the installer or platform designer to mix and match modules to meet the interface requirements in a particular area in a vehicle.

Having the front and rear connectors on the module GVA compliant removes any issues of connecting multiple proprietary subsystems to the platforms electronic architecture by providing an open and predefined electrical interface.

SNAP is not constrained by the GVA standard, SNAP can easily be adapted to meet the NATO GVA standard. As part of the development roadmap, SNAP will also include a number of options to ensure the signal integrity of the high speed Ethernet interfaces.

Key Facts

Fully GVA Compliant Design

Modular Design

Provides Installation Flexibility

Small Form Factor

Can Be Installed On Any Military Vehicle

SNAP forms the interface boundary between the core platform infrastructure and the installed platform subsystems, this ensures that the platform installer has a common interface point into the core infrastructure with a clearly defined and open interface point. This will remove any IPR issues between the providers of the core infrastructure system and the subsystem providers.

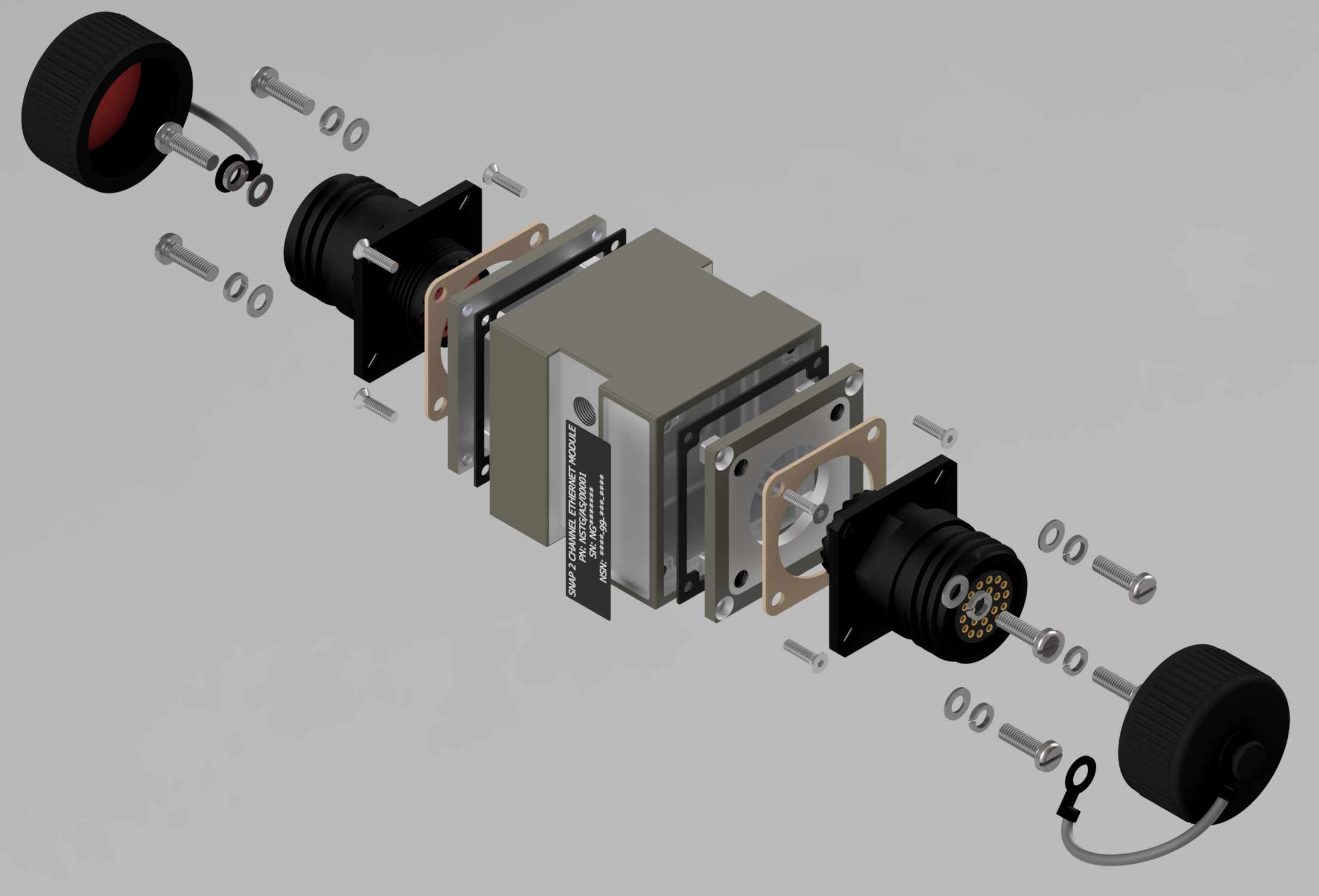

Each module shares a common enclosure design that ensures the inter-connectivity of each module to create a modular patch panel, this is achieved by utilising the two M5 fixing points on each side and a single M5 fixing point on the underside. The side fixing points allows for the connection of the modules in a vertical orientation as well as providing points to connect to the platform adaptor kits. The fixing point on the underside is used to connect the modules in a horizontal orientation and may also be used by the platform adaptor kits as required.

The modules are designed to the smallest form factor possible, with the enclosure measuring only 40mm in all three dimensions. With the small form factor design, this ensures the impact on weight to the platform is minimal, with an average weight of 141 grams (including connectors) per module.

The enclosure design can also be adapted to accommodate all of the connectors defined in the GVA (DEF-STAN 23-09) and NGVA (AEP-4754) standards, by changing the connector holes and fixing points.

Single Port Ethernet

Allows the connection of a single 1Gbps Ethernet port or a single 10/100BASE-T port.

Connectors

FRONT – D38999/20ZB35SN

REAR – D38999/20ZB35PN

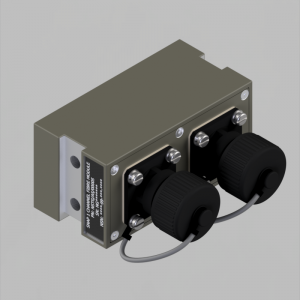

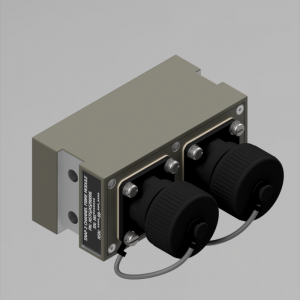

Dual Port Ethernet

Allows the connection of up to two 1Gbps Ethernet ports or two 10/100BASE-T ports.

Connectors

FRONT – D38999/20ZC35SN

REAR – D38999/20ZC35PN

Power

Allows the connection of a single 28VDC equipment requiring a maximum of 25A.

Connectors

FRONT – D38999/20ZC4SN

REAR – D38999/20ZC4PN

Single Channel Fibre

Allows the connection of a single 10Gbps Ethernet port with the ability to support speeds up to 100Gbps.

Connectors

LEFT – 8D0E11Z02BN 674

RIGHT – 8D0E11Z02AN

Dual Channel Fibre

Allows the connection of up to two 10Gbps Ethernet ports with the ability to support up to 100Gbps.

Connectors

LEFT – 8D0E13Z04BN 674

RIGHT – 8D0E13Z04AN

USB

Allows the connection of up to two USB V2.0 devices, also provides 5VDC to each USB device.

Connectors

FRONT – D38999/20ZA35SN

REAR – D38999/20ZA35PN

The Aim

Military platforms come in a number of shapes, sizes and level of system complexity. The key aim of SNAP is to ensure that the design is a one size fits all, this is achieved by giving the installer the flexibility to decide where a patch panel is needed and which modules are required.

Installation Flexibility

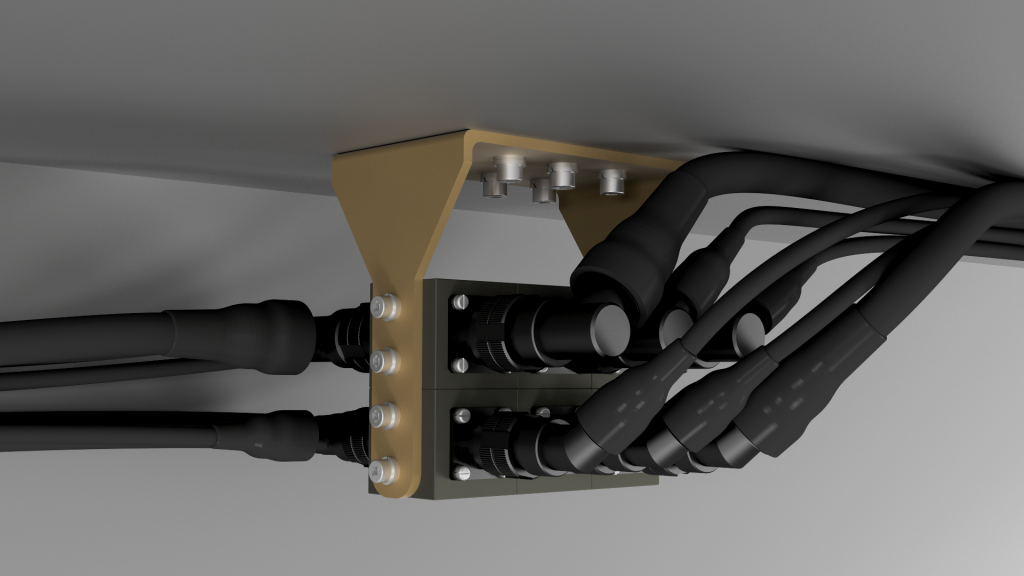

With the modular design and small form factor design of SNAP provides the installer with a huge range of installation options and possible configurations.

Each module has sufficient screening to allow power and data modules to be hosted within the same patch panel, this removes the need to have dedicated patch panels for each type of electrical interface which may not be a beneficial approach for the end user or the platform design.

Each module is provided with a common set of mounting points, with two M5 fixing points on each side of the module and a single M5 fixing point on the underside. These common mounting points allows the installer to quickly calculate the fixing patterns when integrating with the platform adaptor kits.

Each SNAP patch panel once constructed can be mounted in any orientation, to allow the end user optimal access to each patch panel in the platform.

Through Life Updates

With military platforms the first platform system installation is never the last, there is always a need for better, faster and more complex systems. No matter the age of the platform.

The SNAP design allows for a straightforward approach to switching out modules.

As an example, a platform is fitted with a weapon system that requires a patch panel with two 28VDC inputs and four 1Gbps copper Ethernet connections. After five years a new weapon systems is installed that requires two 28VDC inputs and four high speed 10Gbps fibre Ethernet connections.

The impact to design of the SNAP patch panel and the adaptor kit is minimal, the copper Ethernet modules are replaced with the fibre Ethernet modules with zero impact on the adaptor kit design. With each module having a similar mass, there is also minimal impact to the centre of gravity, FEA analysis or safety cases.

SNAP Colour Choice

We understand that NATO green may not be to everyone taste or match the aesthetic of your platforms installation.

So to ensure that your SNAP patch panel doesn’t stand out from the rest of the platform, we’re able to offer the SNAP modules in the following DEF STAN 00-023 complaint colours:

- NATO Green to BS 381C 285

- Camouflage Desert Sand to BS 381C 380

- Black to BS 4800 00 E 53

These colours will be part of our standard range. However, if your installation has a specific requirement we’re able to provide SNAP modules in alternative colours on request.

Require Further Information?

If you require further information about SNAP and how it can be procured and installed on your platform please get in touch. Updates on the development of SNAP will be posted on the NSTG Engineering LinkedIn page.